المنزل الآمن: الحفاظ على الكهرباء والمياه بطرق استثنائية حقًا، عن طريق تأمينها فقط باستخدام متصلات مقاومة للماء

نستخدم الكهرباء يوميًا لإضاءة منازلنا ومدارسنا وحتى الملاعب. الكثير من الماء + الأشياء الكهربائية = سيئ (نحن نعلم أن هذا واضح، لكن لاحظوا أن الماء والكهرباء لا يجتمعان أبدًا.) يمكننا استخدام متصلات مقاومة للماء للحفاظ على البعد بين الكهرباء والماء وتجنب أي خطر.

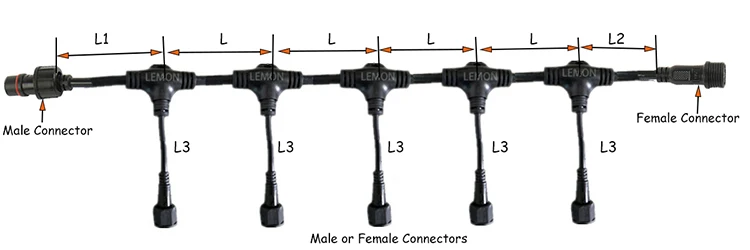

الموصِّلات المضادة لتسرب الماء هي نوع خاص من الأدوات التي تمنع دخول الماء إلى أي مكان يتم فيه استخدام الكهرباء. تم صنع هذه الموصِّلات من مواد غير موصلة للتيار الكهربائي، وكانت تحتوي على أختام حولها لمنع دخول الماء. كوسيلة لإغلاق النظام الكهربائي ومنع التسريبات التي قد تسبب قصر الدائرة أو حتى تؤدي إلى الاشتعال، يتم ذلك باستخدام موصِّلات مضادة لتسرب الماء.

أهمية الموصِّلات المضادة للماء في البيئات العدائية

الموصِّلات المضادة لتسرب الماء ضرورية في أي موقف يمكن أن يؤدي فيه الماء والطين وغيرها من الملوثات البيئية إلى تعريض أداء الاتصالات الكهربائية للخطر. مثلًا، الماء المالح المستخدم في التطبيقات البحرية (القوارب/الأرصفة) يمكن أن يسبب الصدأ والتآكل للمكونات الكهربائية، مما قد يؤدي إلى أعطال أو حتى فشل كامل. في هذه الحالة، من الضروري استخدام موصِّلات مضادة لتسرب الماء للحفاظ على سلامة وأمان النظام الكهربائي بالكامل.

المؤديات المغلقة مائيًا جزء لا يتجزأ من تقديم حماية مقاومة للماء بشكل موثوق في مجموعة واسعة من الصناعات. تشمل التطبيقات الشائعة التركيبات الإضاءة الخارجية، أنظمة الري والعديد من الأعمال الكهربائية الخارجية الأخرى. تُستخدم المؤديات المغلقة مائيًا للحفاظ على اتصالات الكهرباء جافة، مما يمكّن من توفير أنظمة كهربائية خارجية آمنة ويحافظ على كفاءة النظام أيضًا.

الغرض من استخدام هذه المؤديات المغلقة مائيًا بخلاف توفير الحماية للاتصالات الكهربائية من التلف أو الصدأ هو تحسين الأداء. هذه المؤديات تحمي النظام الكهربائي من التعرض للرطوبة أو الملوثات التي يمكن أن تعيق وتمنع تدفق الكهرباء، مما يؤدي إلى تلف المكونات الأخرى في النظام. هذا التحسين في الأداء يجعل توفير الطاقة أمرًا حتميًا، وفي المدى الطويل يؤدي أيضًا إلى تقليل التكاليف.

لخصاً، الشيء الوحيد الذي لا يمكن تجنبه هو اتصال خالي من التسريبات. عند استخدامه في تطبيقات الإضاءة البحرية أو الخارجية، وكذلك في أي بيئة أخرى قد يجتمع فيها الكهرباء والماء، فإنها تحمل أهمية كبيرة للاستقرار الذي توفره لضمان التشغيل المستمر. ما يلي هو وصف مختصر لكيفية قدرتنا على الاستمتاع بالفخامة والراحة دون تدمير أنفسنا أو تعريض أنفسنا للخطر، الموصلات المحكمة ضد الماء.

استنتج أن الموصلات المغلقة مائياً هي عنصر مهم لأي نظام كهربائي في بيئة قاسية حيث يمكن أن يكون مزيج الكهرباء والقرب من الماء خطيراً. توفر الموصلات المغلقة مائياً تشغيل آمن وموثوق للنظام من خلال الحفاظ على السلامة وجفاف الاتصالات الكهربائية. لماذا تهيمن الموصلات المغلقة مائياً على السوق؟ سواء أخذنا بعين الاعتبار تأثير الموصلات المغلقة مائياً في البيئات القريبة من الأجسام المائية أو لأنظمة الكهرباء الخارجية، فهي توفر حلاً آمناً وموثوقاً لمقاومة الماء، مما لا يضيف قيمة إضافية للسلامة فقط بل يساعد أيضاً في الحفاظ على الطاقة وتقليل التكاليف. المرة القادمة التي يخبرك فيها شخص ما عن موصل مغلق مائياً لا يسمح بأي شيء بالمرور من جانب إلى آخر، ولكنه لا يزال قادرًا على الحفاظ على اتصال كهربائي عبر واجهة مغلقة... خذ باليقين أنه هناك عمل متوازي يعمل على الحفاظ على سلامتك وجفافك بينما يسمح لنظام الإضاءة المتلألئة الجديد الخاص بك الذي يكلف 3 دولارات بالعمل بشكل جيد.

واحدة من أكبر الشركات المصنعة عالميًا لأنظمة الكابلات والموصلات، تصنع أنظمة كابلات ذات جودة عالية وموثوقة ومحكمة ضد الماء. نرد على الاستفسارات خلال ساعتين. وقت الإنتاج يتراوح بين 5-10 أيام.

لدى مصنعي الموصلات الكهربائية المحكمة ضد الماء أكثر من 10 سنوات من الخبرة في مساعدة العملاء على تخصيص كابلاتهم بحيث تناسب مواقع التركيب المحددة. يمكننا التخصيص وفقًا لرسوماتكم.

بتبعنا الصارم لمعايير ISO للموصلات الكهربائية المقاومة للماء، نحن قادرون على ضمان الجودة طوال عملية الإنتاج. يشعر العملاء بالثقة أكثر تجاه منتجاتنا. يقوم فريق البحث والتطوير بتطوير وتصميم منتجات جديدة كل شهر.

تركيزنا يكمن في البحث والتطوير وإنتاج إنارة LED الخارجية وكذلك منتجات أنظمة الربط الفوتوVoltaic مثل الكابلات المقاومة للماء والموصلات الكهربائية المقاومة للماء. الأحزمة السلكية وكابلات الطاقة. يتمتع فريق المبيعات لدينا بخبرة تزيد عن 10 سنوات في مجال الكابلات/الموصّلات، ونحن دائمًا قادرون على تقديم إرشادات احترافية.